3D Printing in Dentistry

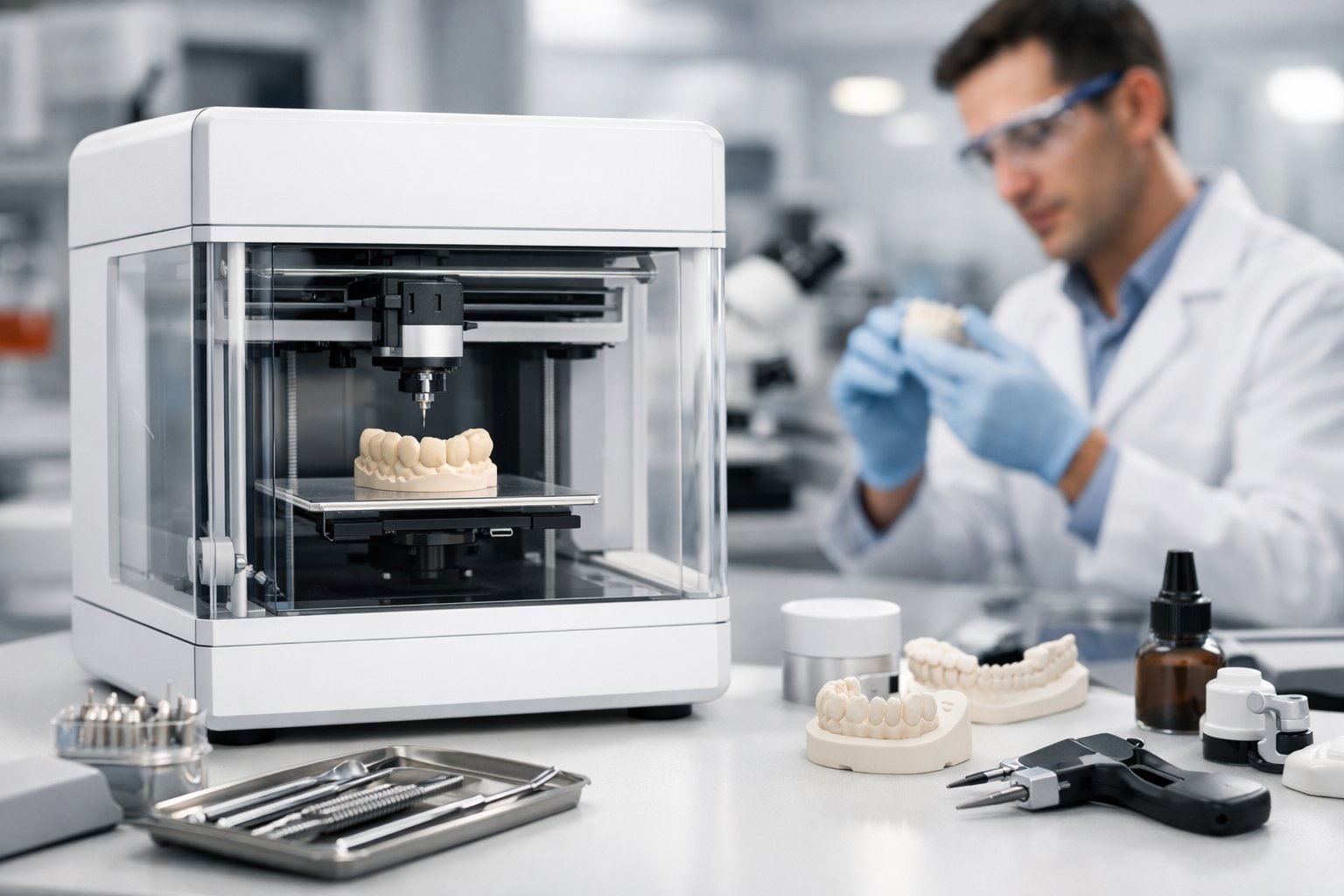

3D printing has changed how dentists create dental devices and treatments for patients. Dentists now use 3D printers to make crowns, bridges, dentures, aligners, and surgical guides faster and more accurately than traditional methods.

This technology lets dental offices produce custom dental work in hours instead of weeks.

Digital dentistry combines computer scanning with additive manufacturing to improve patient care. We can now scan a patient’s mouth with a digital camera, design the dental device on a computer, and print it the same day.

This process removes many steps that used to require sending molds to outside labs.

The shift to 3D printing gives patients better-fitting dental work and shorter wait times. Dentists save money and gain more control over the quality of their work.

Key Takeaways

- 3D printing lets dentists create custom dental devices like crowns, dentures, and aligners in their offices within hours.

- Digital dentistry uses mouth scanning and additive manufacturing to eliminate traditional molds and reduce lab wait times.

- Patients get better-fitting dental work faster, while dentists control quality and lower costs.

Core Technologies and Digital Workflow

Modern dental 3D printing uses different printing methods for various applications. We start the process with digital scans and move through CAD design to final printing and post-processing.

Key 3D Printing Methods in Dentistry

Stereolithography (SLA) uses a laser to cure liquid resin layer by layer. This method creates highly accurate dental models, surgical guides, and temporary crowns.

We often use SLA because it delivers smooth finishes and fine details.

Digital Light Processing (DLP) works like SLA but projects an entire layer at once with a digital light projector. DLP printers work faster than SLA for small batches.

They’re popular for making denture bases and orthodontic models.

Selective Laser Sintering (SLS) uses a laser to fuse powder materials together. This method doesn’t require support structures during printing.

SLS produces durable parts, but we use it less often in dentistry compared to resin-based methods.

Fused Deposition Modeling (FDM) extrudes heated plastic filament to build objects. FDM is less precise than other methods, but some dental labs use it for simple models and prototypes.

Digital Workflow: From Scanning to Printing

We begin with intraoral scanning to capture digital impressions of a patient’s teeth and gums. These scanners replace traditional putty molds.

Some practices also use CBCT scans to capture detailed 3D images of jaw structures and bones.

We move the scan data into CAD software to design the dental appliance, restoration, or model. This software lets us modify designs precisely and check the fit virtually.

After we approve the design, we send the file to the 3D printer. The printer builds the object based on the chosen method and material.

Print times range from 30 minutes to several hours, depending on size and complexity.

Post-processing includes removing support structures, washing excess resin, and curing under UV light. We then polish and finish the object to achieve the required surface quality.

Biocompatible and Specialized Materials

Biocompatible materials meet strict safety standards for oral use. We use FDA-cleared resins for items that contact soft tissue or stay in the mouth temporarily.

These materials resist saliva and don’t release harmful substances.

Dental 3D printing materials include:

- Model resins for accurate study casts

- Surgical guide resins for implant placement

- Temporary crown and bridge resins

- Denture base resins for removable prosthetics

- Castable resins that burn out cleanly for metal casting

Each material needs specific printer settings and post-processing steps. We follow manufacturer guidelines for curing times and temperatures to ensure proper material properties.

Major Applications of 3D Printing in Dentistry

3D printing now creates dental crowns, bridges, veneers, dentures, and clear aligners with greater precision than traditional methods. The technology also makes surgical guides and planning models that improve implant placement accuracy.

Dental Crowns, Bridges, and Veneers

Dental practices use 3D printing to make crowns, bridges, and veneers faster and with better accuracy. We can design, print, and place a 3D-printed crown in a single appointment through chairside restorations.

We start by scanning the patient’s mouth. Then we design the restoration with specialized software and send it directly to a 3D printer.

This process eliminates messy impressions and temporary restorations.

Patients leave with their permanent crown or veneer in one visit instead of waiting weeks. The fit and appearance often surpass traditional lab-made restorations because we control the process digitally.

In-office 3D printing also lowers costs. We avoid paying outside labs and skip shipping.

The materials used in 3D-printed dental prosthetics are durable and biocompatible.

Surgical Guides and Surgical Planning Models

We use 3D-printed surgical guides to improve dental implant placement. These guides fit over a patient’s teeth or gums and direct the drill to the correct position, angle, and depth.

We create surgical planning models from CT scans to view the patient’s anatomy before surgery. These physical models help us spot potential problems and plan the best approach.

We can also design patient-specific implants using these models.

3D-printed surgical guides improve accuracy and patient outcomes. Studies show that using guides leads to more precise implant placement than freehand techniques.

This precision shortens surgery time, reduces tissue trauma, and speeds up recovery.

We use surgical planning models for complex cases like bone grafts or sinus lifts. Holding a physical model helps us practice the procedure and explain the plan to patients.

Dentures, Partial Dentures, and Prosthetics

Digital dentures change how we make complete and partial dentures. We use 3D printing to create denture bases and teeth quickly.

We start with intraoral scanning and design the denture digitally. This method lets us customize tooth position, shape, and color.

We then print the denture base in a biocompatible resin.

Partial dentures also benefit from 3D printing. We can make frameworks that fit more accurately and comfortably than cast metal partials.

We store digital files, so printing replacements is easy if a denture is lost or broken.

Patients get better-fitting dental prosthetics with this process. The accuracy of 3D printing means fewer adjustment appointments.

We also finish dentures faster, which helps patients who need teeth quickly.

Clear Aligners and Orthodontics

We use 3D printing in orthodontics to make clear aligners and orthodontic models. Clear aligners, such as those in popular treatment systems, are made using 3D-printed molds.

We start with a digital treatment plan that maps out tooth movements. We print a series of models for each stage of alignment.

We then form orthodontic aligners over these printed models using a thermoforming process.

We also print diagnostic and orthodontic models for treatment planning and patient records. These models are more durable and easier to store than plaster casts.

We can print them on demand from digital files.

3D printing makes clear aligner treatment more accessible and affordable. The technology lowers production costs and speeds up manufacturing.

Patients get their aligners faster, and dentists can offer better prices.

Clinical Advantages and Patient Benefits

3D printing lets us create custom dental solutions faster than traditional methods. Patients spend less time in the dental chair and get better results.

We can design treatments for each person’s unique mouth structure. Physical models help patients understand their treatment.

Customization and Patient-Specific Solutions

We design dental appliances, crowns, bridges, and orthodontic devices to match each patient’s exact anatomy. Traditional methods use standard sizes or manual adjustments, but 3D printing bases solutions on digital scans.

This customization improves fit and comfort. When we make a crown or denture that matches precise digital measurements, patients need fewer adjustments and get better function.

We use 3D printing for surgical guides in implant placement. These guides fit the patient’s jaw exactly and show us where to place implants at the correct angle and depth.

This precision lowers surgical complications and improves long-term implant success.

Faster Turnaround and Reduced Chair Time

Traditional dental prosthetics often take several appointments over weeks. We can now print many dental devices in our office within hours or days.

Patients spend less time in the dental chair because we need fewer impressions and adjustments. Digital scans replace messy impression materials, and accurate 3D-printed devices mean less time fitting.

For orthodontic aligners, we can print an entire treatment series at once. This reduces the number of office visits.

Emergency replacements arrive faster because we can print them on demand.

Improved Patient Outcomes and Education

Physical 3D-printed models let us show patients exactly what we see in their mouth. We can print a model of their teeth, jaw, or planned treatment so they understand the problem and the solution.

This visual aid improves treatment acceptance. When patients hold a model of their jaw and see where we plan to place an implant, they make better decisions about their care.

We plan treatments more accurately with 3D-printed surgical guides and try-in models. We can test the fit of a restoration before making the final version, which reduces errors.

Better planning leads to more predictable results and higher patient satisfaction.

Challenges, Limitations, and Future Directions

While 3D printing has changed dental practices, we still face challenges with materials, regulations, and technology standards. The field keeps advancing with new biocompatible materials and improved digital workflow systems.

Material and Technology Limitations

Current biocompatible materials for dental 3D printing don’t always match the strength and durability of traditional materials. Resins for crowns and bridges can be more brittle than milled ceramics.

Metal printing for dental frameworks needs expensive equipment that most practices can’t afford.

Common material challenges include:

- Limited color matching for natural teeth

- Shrinkage or warping during printing

- Shorter lifespan than conventional restorations

- High costs for medical-grade printing materials

Post-processing takes time and requires manual work. We must clean, cure, and finish most printed dental products by hand.

This adds time to the process.

The accuracy of additive manufacturing depends on printer calibration and maintenance. Small errors can lead to ill-fitting restorations that need to be reprinted.

Regulatory and Training Considerations

Dental professionals need specialized training to operate 3D printers and design software effectively. Most dental schools are just beginning to include this technology in their curriculum.

A knowledge gap exists between recent graduates and experienced practitioners. The FDA regulates dental 3D printing materials and devices as medical products.

We must submit each new material for approval before we can use it on patients. These approval processes slow down innovation and limit our material choices.

Insurance companies have not standardized coverage policies for 3D printed dental work. Some provide lower reimbursement rates than traditional methods, which affects how quickly practices adopt the technology.

Emerging Trends in Dental 3D Printing

Multi-material printers are developing rapidly and can combine different properties in one print job. These machines let us create restorations with varying hardness levels that better mimic natural teeth.

Artificial intelligence now automates design processes in digital workflow systems. Software can suggest optimal crown shapes based on patient data in seconds.

Key innovations on the horizon:

- Bioprinting with living cells for tissue regeneration

- Faster printing speeds through new light-curing technologies

- Expanded material libraries with improved strength

- Cloud-based design platforms for remote collaboration

Researchers are developing printable antibacterial materials to reduce infection risks around dental implants. Some experimental resins release fluoride or other protective compounds over time.

Frequently Asked Questions

3D printing has changed how dental professionals create crowns, bridges, and aligners. The technology uses specific materials and offers measurable accuracy for different dental applications.

How has 3D printing technology revolutionized dental procedures?

3D printing lets us create dental devices in hours instead of weeks. Traditional methods required multiple patient visits and manual labor from dental technicians.

We can now produce custom aligners, surgical guides, and temporary crowns in a single appointment. The process starts with an intraoral scan and ends with a printed device ready for the patient.

This technology reduces human error in manufacturing. We get consistent results because the printer follows exact digital specifications.

What are the primary materials used in dental 3D printing?

We use photopolymer resins for most dental applications. These materials harden when exposed to specific wavelengths of light during printing.

Biocompatible resins are necessary for devices that stay in a patient’s mouth for extended periods. We also use ceramic materials for permanent crowns and bridges.

Metal printing uses titanium or cobalt-chromium alloys for dental implants and frameworks. Each material type needs different printer technology and post-processing steps.

What is the typical accuracy of dental restorations produced by 3D printing?

Most dental 3D printers achieve accuracy between 25 and 100 microns. This precision works well for crowns, bridges, and dentures.

We measure accuracy by comparing the printed object to the digital design file. Higher-end printers in dental labs reach accuracy levels of 10 to 25 microns.

Accuracy depends on the printer type, material choice, and calibration. We also check how the printed part fits in the patient’s mouth as the final measure of success.

What types of dental applications are most commonly addressed by 3D printing?

We print clear aligners for orthodontic treatment more than any other application. Surgical guides for dental implant placement are also common.

Dental offices frequently print temporary crowns and bridges. We also produce models for treatment planning and patient education.

Denture bases and custom impression trays are popular applications. Night guards and retainers are increasingly made with 3D printing technology.

What are some of the challenges or limitations associated with using 3D printing in dental practices?

The initial cost of professional dental 3D printers ranges from $3,000 to $100,000. We also need to train staff on the software and printing process.

Material costs are high because dental-grade resins cost more than consumer products. Post-processing takes time and requires additional equipment like washing stations and curing units.

Some materials are not yet approved for long-term use in the mouth. We must follow strict regulatory guidelines for each application and material combination.

How does the cost of 3D printed dental solutions compare to traditional manufacturing methods?

3D printing reduces labor costs because technicians spend less time on each item. Printing in-house also eliminates shipping fees and waiting time.

Custom one-off items like surgical guides cost less per unit with 3D printing. Traditional methods are cheaper for large runs of identical items.

A 3D printed crown uses $5 to $15 in materials. Lab-made crowns use $50 to $150 in materials.

We save money on storage since we print items as needed instead of keeping inventory.

📞 Contact Kaufman Dentistry Today

Give us a call at (310) 838-7780 to schedule your appointment and take the first step towards a stunning smile.

You can find us at 10760 Washington Blvd., Culver City, CA 90232. We look forward to welcoming you to our practice and helping you achieve the smile of your dreams!